October 02, 2007

Straight Razor Maintenance

Honing the straight razor is probably the biggest challenge faced by the beginning straight razor shaver. Even brand-new razors from respected manufacturers like Dovo or Thiers-Issard aren't really sharp enough for a comfortable shave and must be honed before use.

There are really two basic phases in razor honing. The first phase (and probably the hardest) is simply getting the razor shaving-sharp in the first place. The second phase keeping it that way.

The first problem can be solved by buying the razor from a company like Classic Shaving that offers a professional honing service, or by sending the razor out to a skilled razor honer. Doing it yourself is certainly possible but requires a great deal of practice and some potentially expensive equipment.

If you are trying to use a straight razor for your daily shaver the most important problem is keeping the razor sharp. The first prerequisite is stropping the razor before each shave. Contrary to what you may have been led to believe, stropping does *not* sharpen the razor. It simply cleans the edge of any corrosion that may have developed overnight (and there will have been some, at the microscopic level) and helps straighten it out similar to the way a chef uses a knife steel. Stropping will help extend the life of the edge but eventually the edge will deteriorate and will need honing to recover its shaving ability. How long a razor can go between honings depends on a variety of factors such as the wiriness of your beard, the quality of your stropping technique, and the corrosiveness of the environment (humidity kills razors). Some people also have naturally acidic or salty skin that also tends to reduce the life of the edge.

There are two main flavors of strop in common use in the US: the traditional hanging strop (usually hung from a carriage bolt or the doorknob), and a paddle strop which is basically a board covered in leather with a handle attached. There is a third type called a loom strop that is sometimes found in Europe. This is a paddle-type strop with a stretcher mechanism inside a loop of leather, and it combines the small size of the paddle strop with the stropping "feel" of a hanging strop.

As the razor's edge degrades over a few weeks (or months) of shaving it will eventually start pulling at your whiskers a bit, and if this cannot be cured by additional stropping then it is time to refresh the edge by removing some metal. One of the most easily mastered method of doing this is the abrasive strop. This simply requires the user to repeat his well-practiced stropping motion, and the abrasives embedded in the strop will return the razor to shaving form in only a few laps. Some experienced straight razor shavers prefer to refresh their razor on the same water hones that were used to put on the initial edge. And around the turn of the century most barbers used small specialized ceramic hones that have come to be known as "barber hones"; though these are no longer being made they are readily available on ebay. However, barber hones and water hones are more difficult to master than the abrasive strop, and are best left until a new shaver has gotten a little more experience, if only to avoid unnecessary learning curves early on.

Both paddle strops and hanging strop may be embedded with abrasives and used to sharpen a razor. Paddle strops are probably the most commonly used form of abrasive strop today, but according to my father (who lived with his grandparents for many years during and after WWII), my great-grandfather never used a stone on his razor. He kept it sharp all those years using only his hanging strop which apparently had some sort of abrasive on the linen side. I have both types myself, and find that they both work well, though the abrasive hanging strops seem to be more aggressive.

One place where I think the abrasive hanging strops really have no peer is sharpening the big Sheffield choppers. These razors tend to be huge and heavy and have equally huge bevels, and fine-grit stones are simply too slow to put a really sharp edge on the razor in a reasonable amount of time. But the hanging strops have 15 inches or so of stroke instead of the 6 or 7 inches on a hone or abrasive paddle, so they get the job done much more quickly. Even the biggest Sheffield razor can be refreshed with only a few dozen strokes on an abrasive hanging strop.

My favorite abrasives on these strops are 1.8 micron boron carbide and 0.5 micron chromium oxide. I also have a hanging strop with one side treated with Flexcut Gold, whis is a coarse fast-cutting abrasive that is used for rough work on the big Sheffields as well as sharpening our chef's knives and my pocketknives.

Photos below...

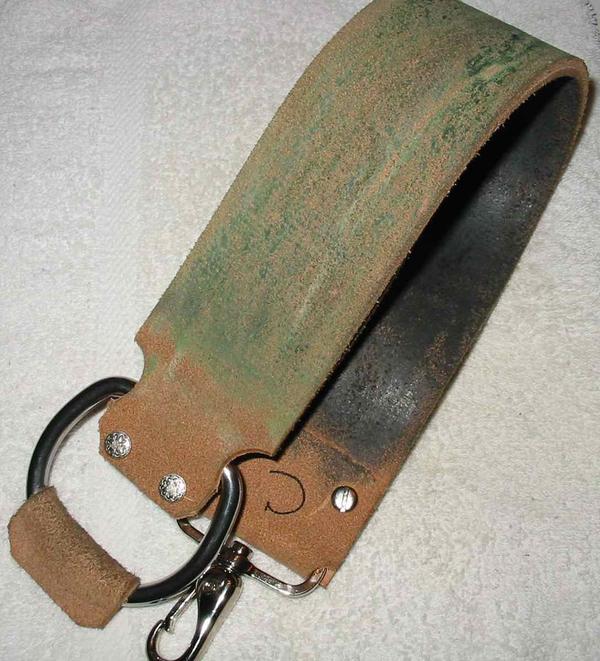

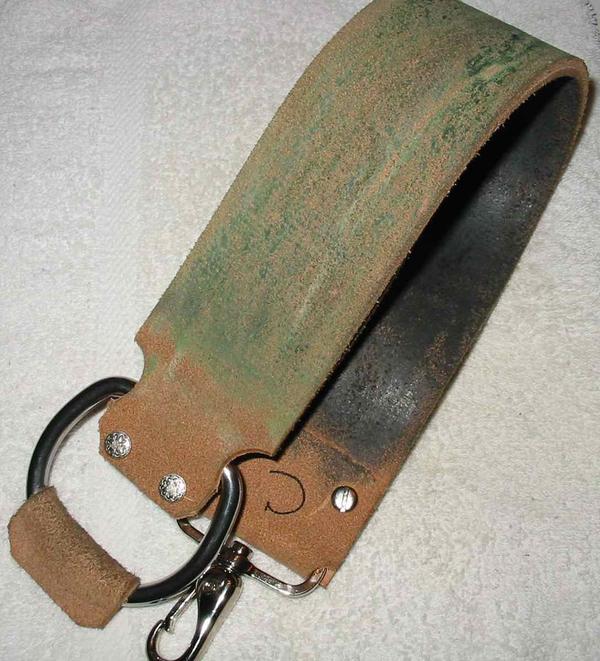

Traditional hanging strop. This one is made by the Illinois Strop Company. Despite the horse logo on the strop, it is cowhide and not horsehide.

Abrasive hanging strop made by Hand American. The yellow-green side is coated with Flexcut Gold, the black side is coated with 1.8 micron Boron Carbide. This particular strop is made with the rough side of the leather facing out, so it holds more abrasive for faster cutting.

The Illinois strop pictured above also has chromium oxide (0.5 micron) on the linen side. This abrasive is applied thinly because I do not want it to cut very fast - this side is for refreshes only, and if it were pasted heavily then it would remove too much metal. Chromium oxide is normally bright green - the abrasive here is a greenish-brown because of accumulated metal mixed in with the abrasive. It will eventually turn black.

I also have a small paddle that I use on trips. This one is very short and narrow to pack easier, and has one plain leather side for daily stropping and chromium oxide on the other side for refreshes.

Plain side:

Pasted side:

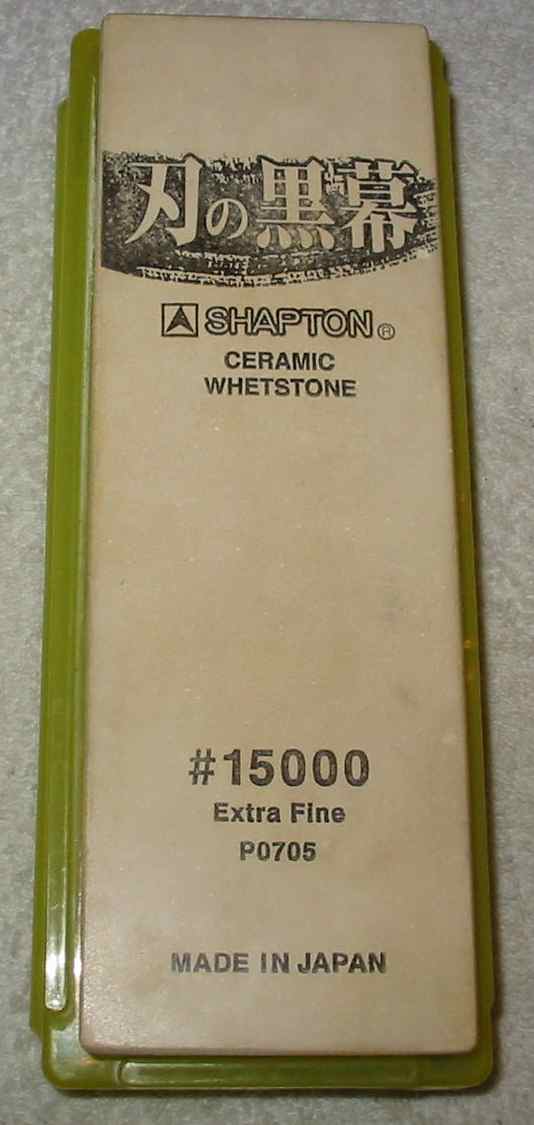

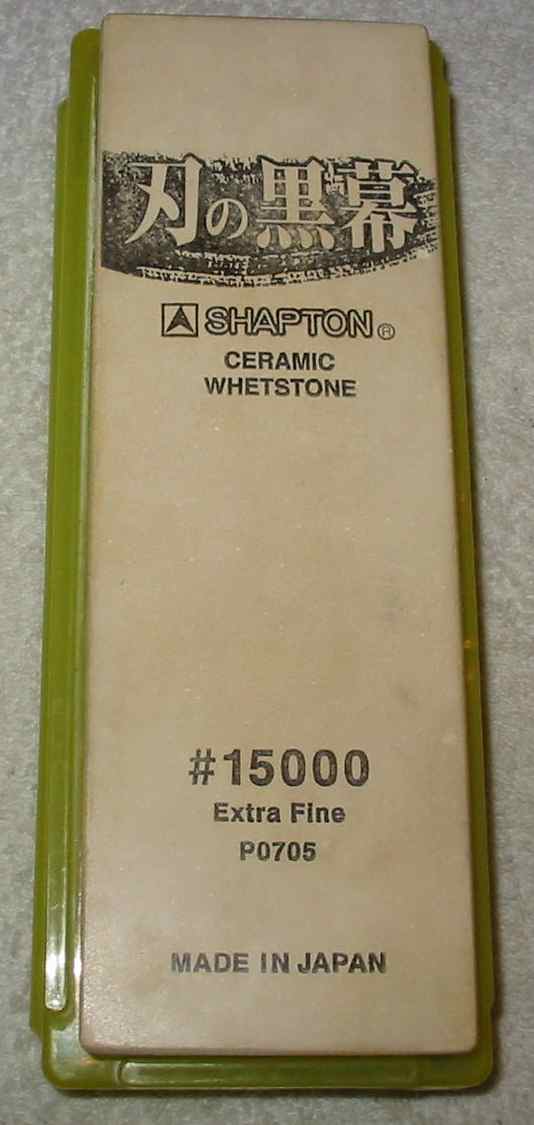

Waterstone - this one is the Shapton 15,000 grit hone, which is a synthetic Japanese hone. Shapton makes a variety of hones from 100 grit up to 30,000 grit. By way of comparison most knife hones are in the 400-800 grit range, and Arkansas stones are about 1,000 grit. Shaptons are my hone of choice for the initial sharpening. Stones are better for the first sharpening because they will cut a nice straight edge and take out any nicks or waviness in the blade. (The back side of this hone is the working side).

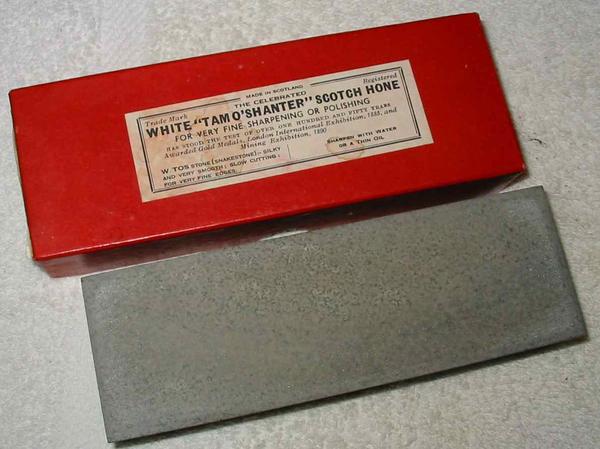

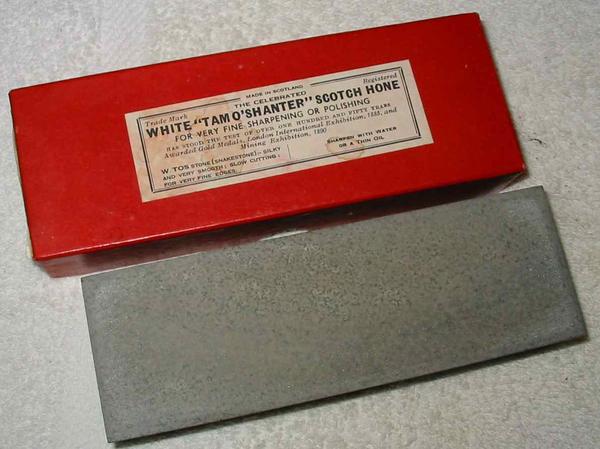

This hone is a traditional natural hone from Scotland. The mine for these recently closed down due to new E.U. regulations. This particular hone is about 6k grit, but like most natural stones it is a slow cutter, and seems to make a nicer edge than the grit rating would indicate.

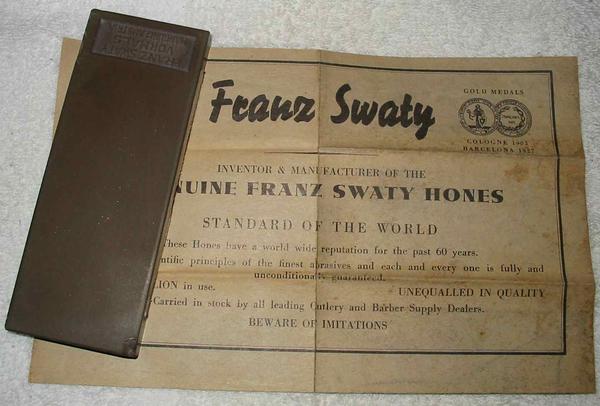

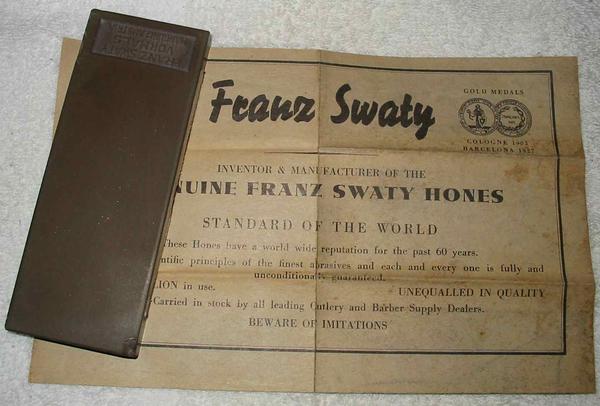

Barber hones were very popular in the late 1800's through the end of the straight razor era. This one is a Franz Swaty 3-line hone (so called because of the three lines of text at the end). The sheet that came with it in the box mentions a medal at Barcelona in 1927, so this hone is relatively recent. The Swaty hone is quite common on ebay and is widely recognized as a good performer.

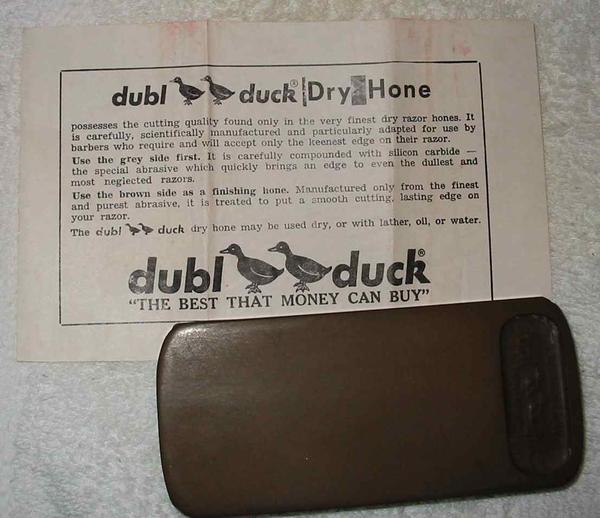

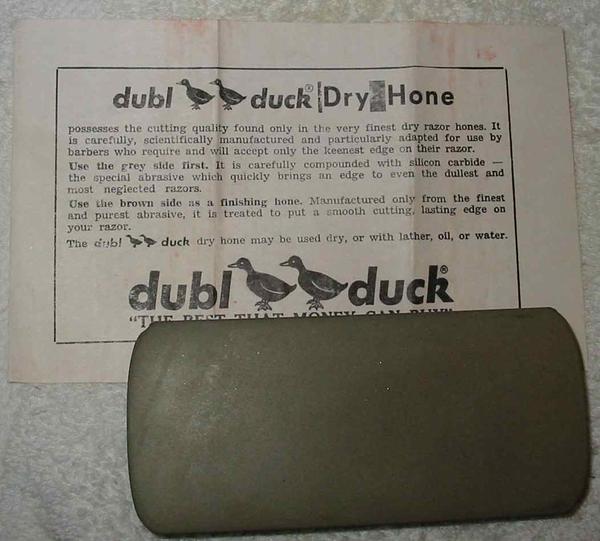

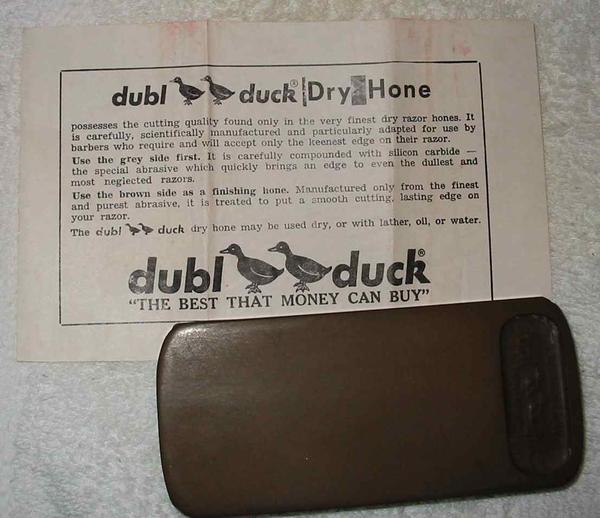

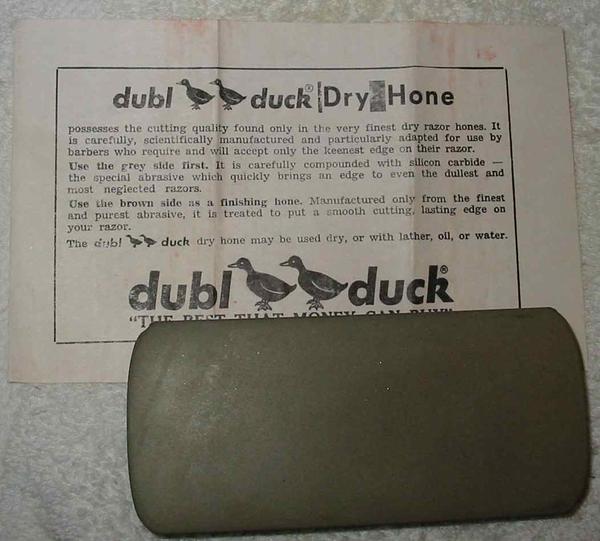

My favorite barber hone is the Dubl Duck combination hone, with both coarse and fine grits on opposite sides.

Fine side (brown):

Coarse side (light gray):

Comments are disabled.

Post is locked.

There are really two basic phases in razor honing. The first phase (and probably the hardest) is simply getting the razor shaving-sharp in the first place. The second phase keeping it that way.

The first problem can be solved by buying the razor from a company like Classic Shaving that offers a professional honing service, or by sending the razor out to a skilled razor honer. Doing it yourself is certainly possible but requires a great deal of practice and some potentially expensive equipment.

If you are trying to use a straight razor for your daily shaver the most important problem is keeping the razor sharp. The first prerequisite is stropping the razor before each shave. Contrary to what you may have been led to believe, stropping does *not* sharpen the razor. It simply cleans the edge of any corrosion that may have developed overnight (and there will have been some, at the microscopic level) and helps straighten it out similar to the way a chef uses a knife steel. Stropping will help extend the life of the edge but eventually the edge will deteriorate and will need honing to recover its shaving ability. How long a razor can go between honings depends on a variety of factors such as the wiriness of your beard, the quality of your stropping technique, and the corrosiveness of the environment (humidity kills razors). Some people also have naturally acidic or salty skin that also tends to reduce the life of the edge.

There are two main flavors of strop in common use in the US: the traditional hanging strop (usually hung from a carriage bolt or the doorknob), and a paddle strop which is basically a board covered in leather with a handle attached. There is a third type called a loom strop that is sometimes found in Europe. This is a paddle-type strop with a stretcher mechanism inside a loop of leather, and it combines the small size of the paddle strop with the stropping "feel" of a hanging strop.

As the razor's edge degrades over a few weeks (or months) of shaving it will eventually start pulling at your whiskers a bit, and if this cannot be cured by additional stropping then it is time to refresh the edge by removing some metal. One of the most easily mastered method of doing this is the abrasive strop. This simply requires the user to repeat his well-practiced stropping motion, and the abrasives embedded in the strop will return the razor to shaving form in only a few laps. Some experienced straight razor shavers prefer to refresh their razor on the same water hones that were used to put on the initial edge. And around the turn of the century most barbers used small specialized ceramic hones that have come to be known as "barber hones"; though these are no longer being made they are readily available on ebay. However, barber hones and water hones are more difficult to master than the abrasive strop, and are best left until a new shaver has gotten a little more experience, if only to avoid unnecessary learning curves early on.

Both paddle strops and hanging strop may be embedded with abrasives and used to sharpen a razor. Paddle strops are probably the most commonly used form of abrasive strop today, but according to my father (who lived with his grandparents for many years during and after WWII), my great-grandfather never used a stone on his razor. He kept it sharp all those years using only his hanging strop which apparently had some sort of abrasive on the linen side. I have both types myself, and find that they both work well, though the abrasive hanging strops seem to be more aggressive.

One place where I think the abrasive hanging strops really have no peer is sharpening the big Sheffield choppers. These razors tend to be huge and heavy and have equally huge bevels, and fine-grit stones are simply too slow to put a really sharp edge on the razor in a reasonable amount of time. But the hanging strops have 15 inches or so of stroke instead of the 6 or 7 inches on a hone or abrasive paddle, so they get the job done much more quickly. Even the biggest Sheffield razor can be refreshed with only a few dozen strokes on an abrasive hanging strop.

My favorite abrasives on these strops are 1.8 micron boron carbide and 0.5 micron chromium oxide. I also have a hanging strop with one side treated with Flexcut Gold, whis is a coarse fast-cutting abrasive that is used for rough work on the big Sheffields as well as sharpening our chef's knives and my pocketknives.

Photos below...

Traditional hanging strop. This one is made by the Illinois Strop Company. Despite the horse logo on the strop, it is cowhide and not horsehide.

Abrasive hanging strop made by Hand American. The yellow-green side is coated with Flexcut Gold, the black side is coated with 1.8 micron Boron Carbide. This particular strop is made with the rough side of the leather facing out, so it holds more abrasive for faster cutting.

The Illinois strop pictured above also has chromium oxide (0.5 micron) on the linen side. This abrasive is applied thinly because I do not want it to cut very fast - this side is for refreshes only, and if it were pasted heavily then it would remove too much metal. Chromium oxide is normally bright green - the abrasive here is a greenish-brown because of accumulated metal mixed in with the abrasive. It will eventually turn black.

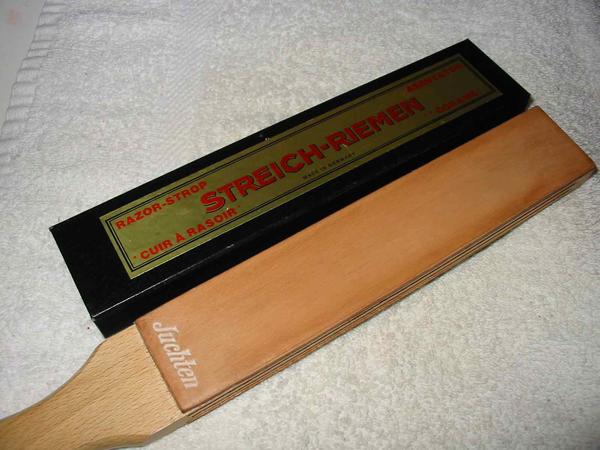

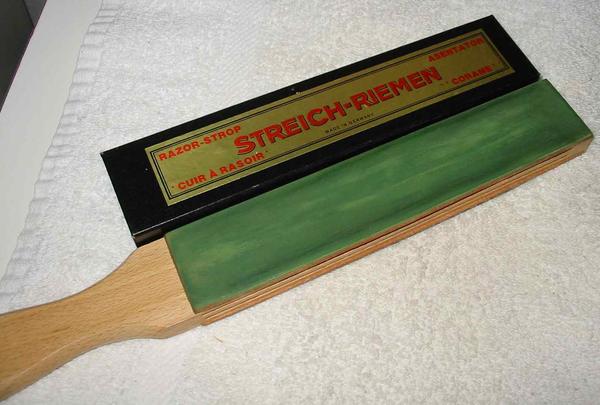

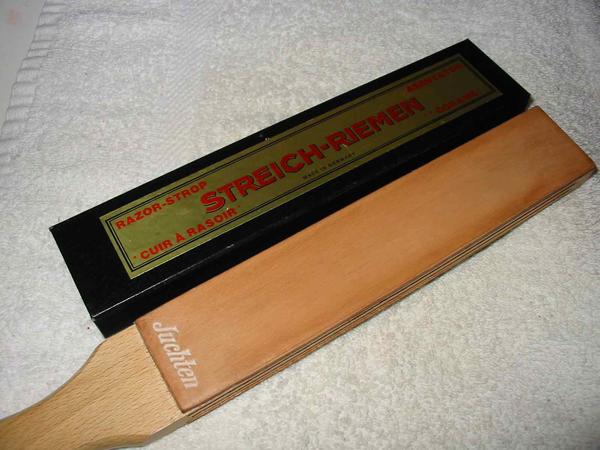

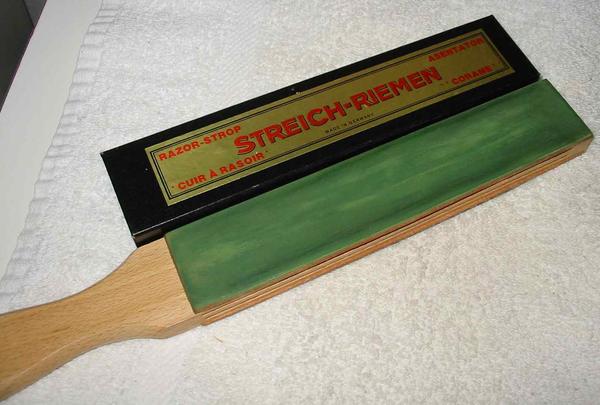

I also have a small paddle that I use on trips. This one is very short and narrow to pack easier, and has one plain leather side for daily stropping and chromium oxide on the other side for refreshes.

Plain side:

Pasted side:

Waterstone - this one is the Shapton 15,000 grit hone, which is a synthetic Japanese hone. Shapton makes a variety of hones from 100 grit up to 30,000 grit. By way of comparison most knife hones are in the 400-800 grit range, and Arkansas stones are about 1,000 grit. Shaptons are my hone of choice for the initial sharpening. Stones are better for the first sharpening because they will cut a nice straight edge and take out any nicks or waviness in the blade. (The back side of this hone is the working side).

This hone is a traditional natural hone from Scotland. The mine for these recently closed down due to new E.U. regulations. This particular hone is about 6k grit, but like most natural stones it is a slow cutter, and seems to make a nicer edge than the grit rating would indicate.

Barber hones were very popular in the late 1800's through the end of the straight razor era. This one is a Franz Swaty 3-line hone (so called because of the three lines of text at the end). The sheet that came with it in the box mentions a medal at Barcelona in 1927, so this hone is relatively recent. The Swaty hone is quite common on ebay and is widely recognized as a good performer.

My favorite barber hone is the Dubl Duck combination hone, with both coarse and fine grits on opposite sides.

Fine side (brown):

Coarse side (light gray):

Posted by: mparker762 at

12:25 PM

Post contains 1269 words, total size 9 kb.

18kb generated in CPU 0.0103, elapsed 0.0296 seconds.

42 queries taking 0.0224 seconds, 101 records returned.

Powered by Minx 1.1.6c-pink.

42 queries taking 0.0224 seconds, 101 records returned.

Powered by Minx 1.1.6c-pink.